NSI Draughtsman Syllabus 2026 – Complete Topic-wise Breakdown

Contents

✓ Verified against National Sugar Institute (NSI) Notification No. 1/2026. All topics for Written and Skill tests reproduced verbatim.

The National Sugar Institute (NSI), Kanpur, requires Draughtsmen to possess a high degree of precision in mechanical drafting and computer-aided design. The selection process involves a Skill Test (Qualifying) followed by a Written Examination (Merit-based).

Exam Pattern Overview (2026)

| Stage | Mode | Nature | Marks |

| Stage 1: Skill Test | Practical/Trade Test | Qualifying | Pass/Fail |

| Stage 2: Written Test | Objective/Subjective | Merit-Ranking | 100 Marks |

Export to Sheets

- Written Test Duration: 3 Hours.

- Skill Test: Focuses on CAD proficiency and manual drawing accuracy.

- Merit: Final selection is based solely on the Written Test score for candidates who qualify the Skill Test.

Written Examination Syllabus (Verbatim)

1. Fundamental Drawing Principles

- Nomenclature, description, and use of drawing instruments & various equipment used in drawing office. Their care and maintenance.

- Layout of a drawing sheet as per B.I.S. (Bureau of Indian Standards).

- Lines and their meanings; type of lettering, proportion, and spacing of letters and words.

- Terms & definitions: Polygons and circles.

- Definition of ellipse, parabola, hyperbola; different methods of their construction.

- Definition & method of drawing cycloid curves, helix, and spirals.

2. Projections & Geometry

- Terminology: Feature, functional feature, functional dimension, datum dimension, and principles.

- Units of dimensioning, systems of dimensioning, and methods for common features.

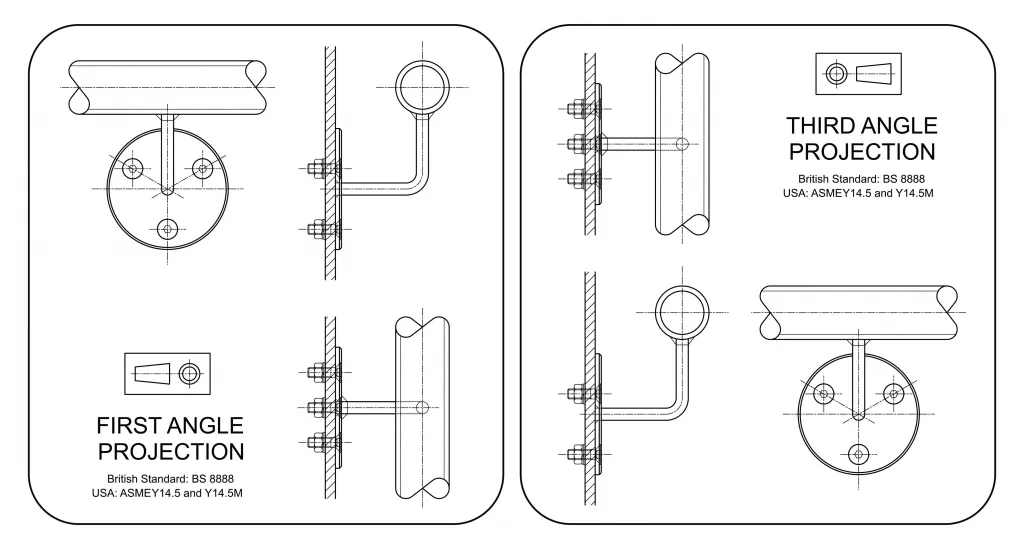

- Planes and their normal projections; orthographic projection (First angle and third angle).

- Projections of solids: Prisms, cones, pyramids, and frustums in various positions.

- Construction of different types of scales: Principle of R.F., diagonal, and Vernier scales.

- Sectional views: Importance, types, and parts not shown in section.

- True shape of surfaces: Solids cut by different cutting planes.

- Development of surfaces: Industrial need and methods of developing surfaces.

- Intersections & Interpenetration: Intersection of prisms, cones, pyramids, and cylinders with intersecting axes.

3. Machine Drawing & Fasteners

- Screw Threads: Terms, nomenclature, types, proportions, uses, and thread conventions.

- Nuts & Bolts: Types of nuts, bolts, studs, and locking devices (Machine screws, cap screws, set screws).

- Foundation Bolts: Different types and applications.

- Riveted Joints: Fastening materials, types of rivets, efficiency of joints, and causes of failure.

- Welded Joints: Representation (Actual and Symbolic) and Welding Symbols as per BIS.

4. Mechanical Components & Systems

- Keys, Cotters & Pins: Purpose, types (Heavy/Light duty), and use of cotters and pins.

- Couplings: Necessity, classification, materials, and proportions of different types.

- Bearings: Frictional and anti-frictional bearings (Ball, roller, thrust, needle, and taper roller); materials and properties.

- Power Transmission: Belts (materials, slip, creep, velocity ratio), Pulley ratio, and V-belt drive calculations.

- Gears: Types of gears (Cast vs. Machined), use of Nomographs for drawing gear profiles.

- Cams: Types of cams and followers, displacement diagrams, and kinds of motion.

- Piping: Specifications of W.I. & Steel pipes, pipe threads, and fittings.

5. Advanced Engineering Tools & Principles

- Engines: Brief description of Petrol, Diesel, and Gas engines.

- Hydraulics: Working principle of valves, hydraulic jacks, presses, accumulators, and rams.

- Structural Steel: B.I.S. Specifications for rolled sections, roof truss joints, and supports.

- Measurement: Precision instruments like Vernier height gauges, micrometers, and gauges.

- Limits, Fits & Tolerances: Geometrical tolerance, surface finish symbols (grades and micron values), and IS:919/IS:2709 standards.

Skill Test Syllabus (Practical)

Candidates will be assessed on their ability to perform the following tasks:

- Documentation: Preparing industrial documents and recording information.

- Geometrical Construction: Drawing complex figures using manual instruments.

- Orthographic & Sectional Views: Drawing detailed machine parts with proper title blocks and dimensions.

- CAD Proficiency: * Creating objects in CAD using toolbars, commands, and menus.

- 3D Modeling: Creating 3D objects and converting them to 2D projections.

- Customizing layers, styles, and creating standard templates/callouts.

- Assembly & BOM: Creating part lists and Bill of Materials (BOM) for sub-assemblies.

- Inspection: Measuring components using gauges and checking for accuracy (ISO tolerances).

Strategic Preparation Guide

- BIS Standards: Focus heavily on IS:919 (Tolerances) and IS:2709 (Fits). NSI technical exams often ask specific questions about standard symbols used in drawing.

- CAD Shortcuts: For the Skill Test, master AutoCAD commands (L, O, EX, TR, CO) to save time, as speed is often a qualifying factor.

- Manual Drawing: Don’t neglect manual lettering and scales. At least 20% of the theory marks often come from fundamental drawing instruments and geometry.

- Mechanical Knowledge: Since the eligibility requires a Diploma in Mechanical Engineering, expect detailed questions on Thermal Engineering basics (Engines) and Fluid Mechanics (Hydraulic Jack).

Official Resources

- Official Website: nsi.gov.in

- Recruitment Portal: NSI Career Page

- Application Deadline: March 15, 2026.